Products&Technology

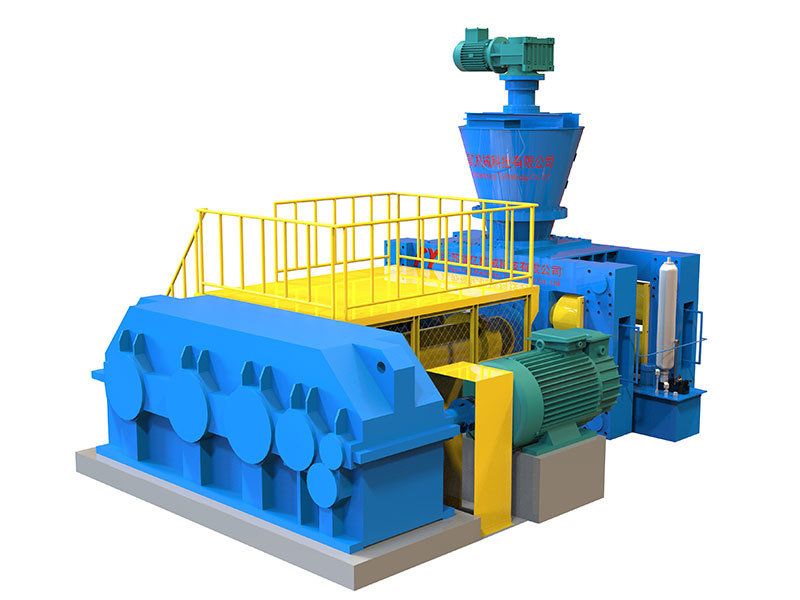

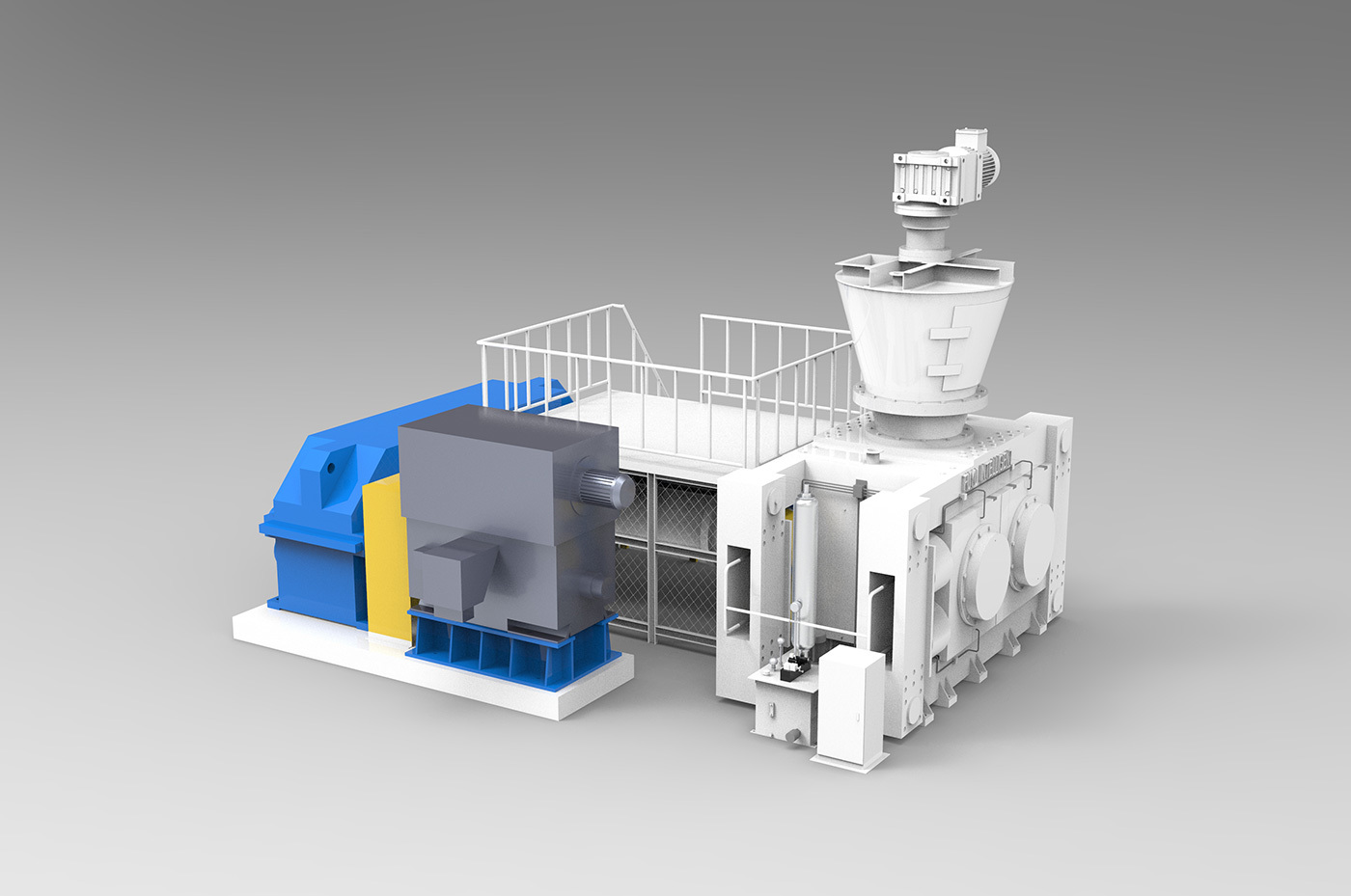

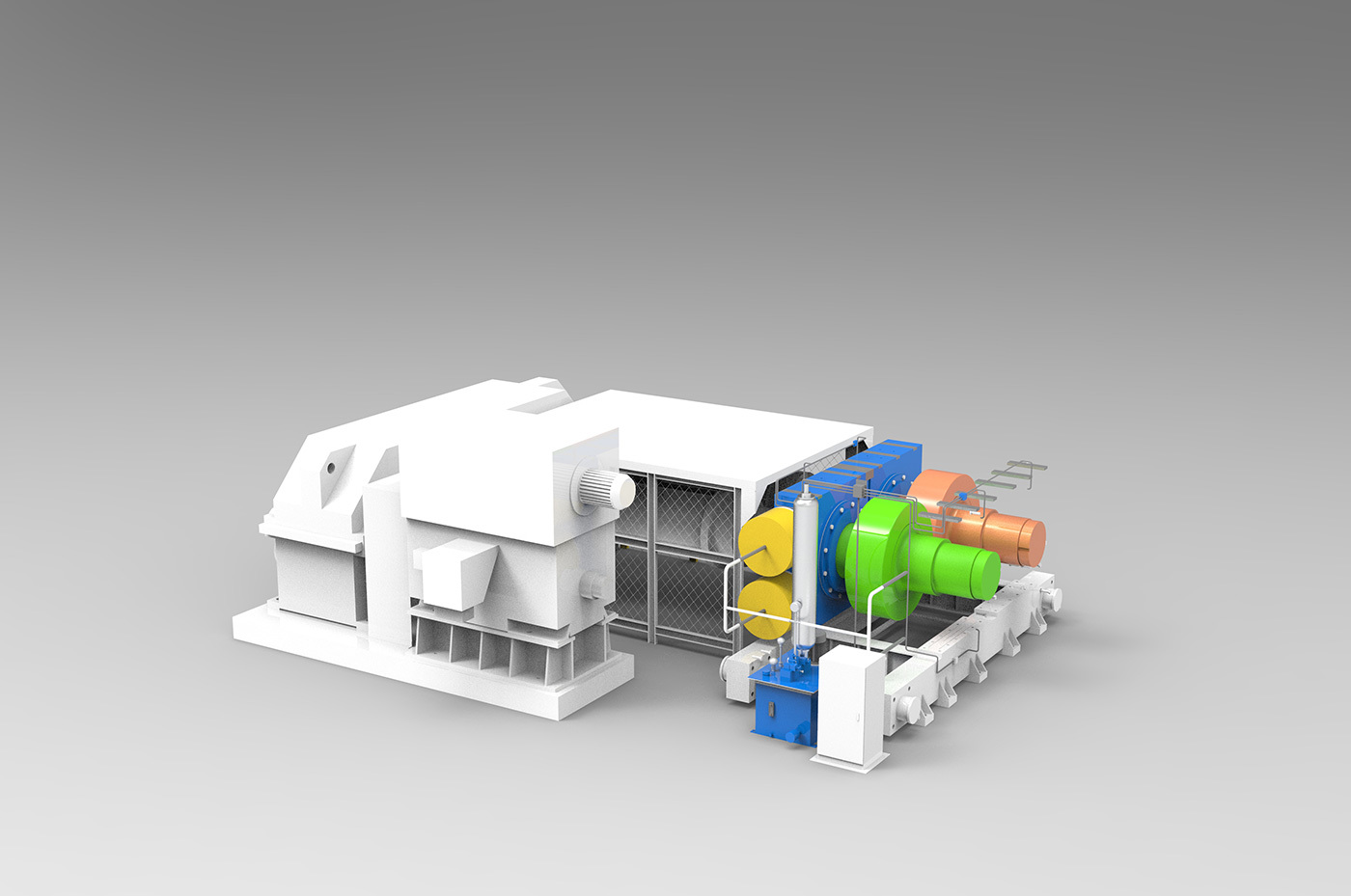

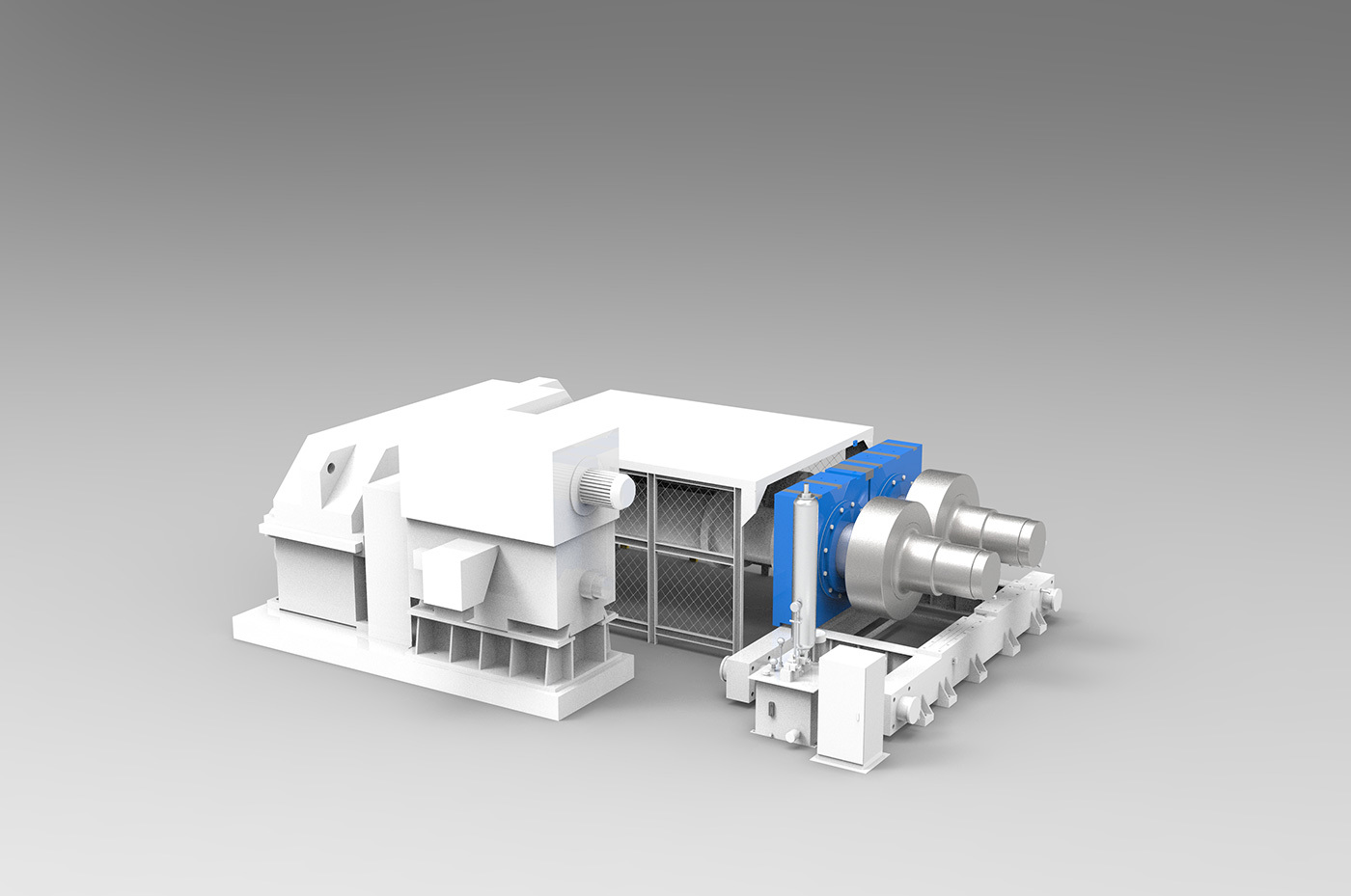

ROLLS DRIVE

The rollers are driven by an electric motor in combination with a double-shaft gear box and tooth couplings. This system synchronizes the rollers and allows for the movement of the floating roller.

And our equipment provides the choice of ordinary motors and high-voltage motors.

HYDRAULIC SYSTEM

The fixed roller(red) is supported directly in the press frame, while the so-called floating roller(green) is also supported in the frame. The movement of the floating roller constitutes the basic principle of a roller press.

Controlling the material feed into the roller nip is of paramount importance, whereby a gravity feeder can be used for materials with sufficient flow properties. Other materials may require a screw feeder that forces the material into the nip between the rollers.

HYDRAULIC SYSTEM

The hydraulic system provides pressure to compact the material bitten by the rollers.

The pressure level can be adjusted. The pressure is adjusted as the distance between the rollers varies.

The force applied on the product can vary from 5 to 220 KN/Lcm.

The hydraulic system is also used as a safety device. It ensures the strength of the rolled sheet and ensures the safety of the equipment.

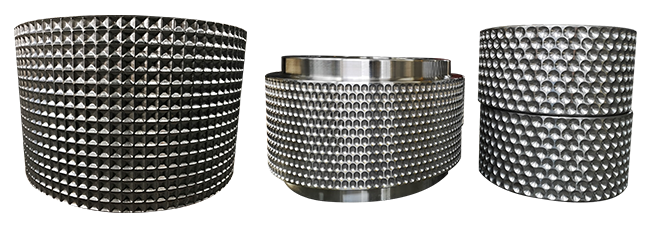

Round, Oblate, Custom shape

01

02

03

Design Feature

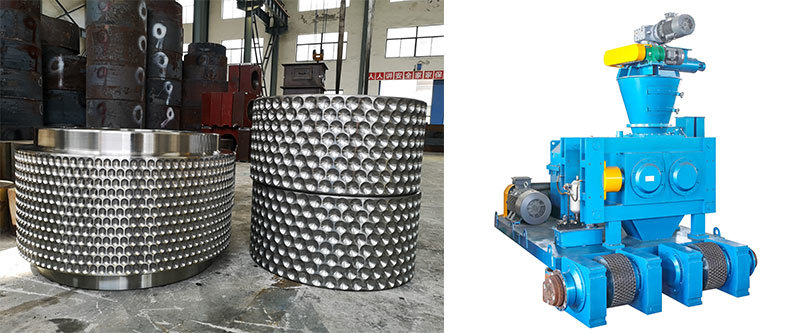

Modular Construction for Customized Flexibility

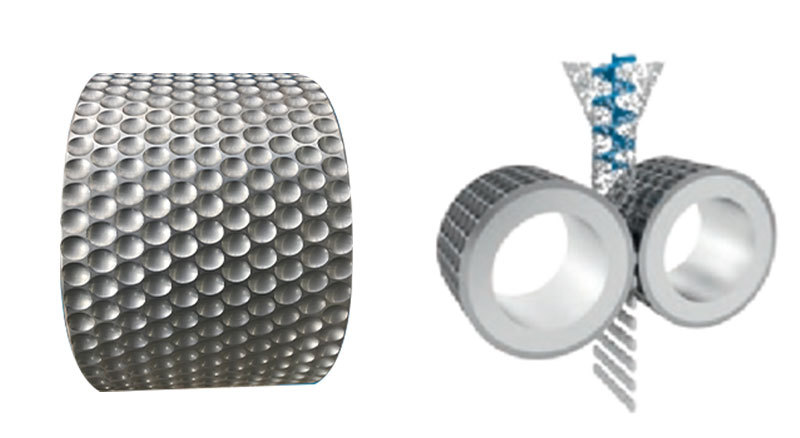

Briqutting with roller presses follows a simple princifble: a fine raw material is fed into the space between two counter-rotating rollers, where it is then compressed and formed into briquettes.

The main functional assemblies provided for this purpose arei

● Press frame

● Pressing rollers with bearings and bearing housings

● Main drive with reduction gear

● Material feeder: Quantitative screw feeding and forced screw feeding

● Hydraulic pressuring system

● Greaselubrication

● Roller housing

The fixed roller is supported directly in the press frame, while the so-called fioating roller is also supported in the frame. The movement of the floating roller constitutesthe basic principle of a roller press. The roller are driven by an electric motor in combination with a double-shaftgear box and tooth couplings. This system synchronizes the rollers and allows for the movement of the floating roller. Controlling the material feed into the roller nip is of paramount importance, whereby a gravity feeder can be used for materials with sufficient flow properties. Othel materials may require a screw feeder that forces the material into the nip between the rollers. The pressing drums are designed as round, or oblateor clam segments, and are fitted with pockets of the ell eoinues unulxeu buynsue snu 'lueisisel-jeem pueAppseiespolfursseidIAndelisedeyspueezispealspealsep and minimum expense. Refurbished pressing tools with a smaller than nominal diameter can also be used. A roller housing is provided for safely reasons and to rrinirrize dust errission.

Equipment parameters

| Model | DH240 | DH360 | DH450 | DH650 |

| Roller diameter(mm) | Φ240 | Φ360 | Φ450 | Φ650 |

| Valid usable width of roller (mm) | 100-160 | 170-300 | 190-280 | 290-450 |

| Rotation rate(rpm) | It can be adjusted on site according to different material characteristics. | |||

| Finished product granule size (mm) | Customized according to customer requirements | |||

| Max.press force (KN/cm) | 35 | 49 | 68 | 100 |

| Compactor power(KW) | 22 | 30-37 | 55-75 | 110-132 |

| (L.W.H) External dimension (mm) | 2300x1700x1860 | 2350x2000x2600 | 2600x2200x2900 | 3600x2800x3200 |

| Compactor weight(t) | 5 | 7 | 10 | 21 |

| Model | DH850 | DH1050 | DH1250 | DH1550 |

| Roller diameter(mm) | Φ850 | Φ1050 | Φ1250 | Φ1550 |

| Valid usable width of roller (mm) | 420-450 | 450-500 | 650 | 650 |

| Rotation rate(rpm) | It can be adjusted on site according to different material characteristics. | |||

| Finished product granule size (mm) | Customized according to customer requirements | |||

| Max.press force (KN/cm) | 180 | 361 | 450 | 550 |

| Compactor power(KW) | 220-250 | 400 | 630 | 630*2 |

| (L.W.H) External dimension (mm) | 500×3800×4100 | 7000×5000×6000 | 9700×5600×7700 | 10500×6000×8100 |

| Compactor weight(t) | 46 | 85-95 | 120-150 | 200-220 |

Process Technology

Briquetting without Binder

A number of substances can be converted into product of adequate strength without the addition of a binding agent. The material must of course possess inherent binding properties, whereby the bonding can be achieved in a number of different ways:

Plastification under pressure

Structures(crystalline or non-crystalline) are forced into each other and when the pressure is then reduced, the structures rearrange themselves and form an almost natural bond. This effect can for example be observed in various salts(NaCl, KCI) or metals.

Binder “on board”

One example is the lignin contained in biomass. On being subjected to pressure, the inherent lignin is squeezed out of the original structure into the voids between the particles.

Mechanical linkage

The particles interlink on account of their shape (e.g.metal turnings).

Capillary forces

Small water bridges from the bond between the particles. This requires a fine particle size distribution along with the correct proportion of water. The briquettes are soft and their physical properties are not suited to severe handling or transportation situations.

The briquetting process as such is quite simple. Raw material are metered out and homogenized before being fed to the roller press.FUYI tailors the roller press to the customer's requirements in terms of the:

● gravity feeder/screw feeder

● roller speed

● (specific) press force

● torque of the main drive

● briquette size and shape

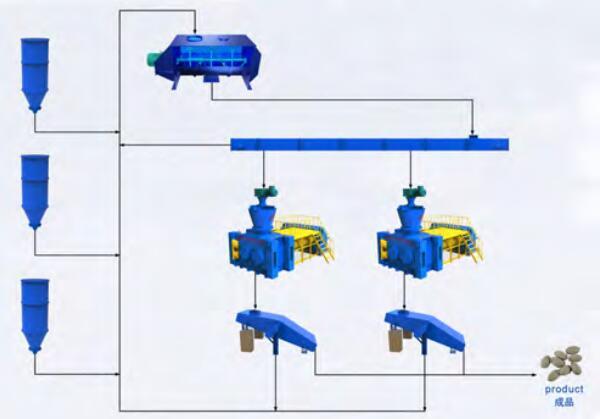

● number of roller presses

● etc The roller press output can be screened so that undersize material is recycled back to the roller press.

Briquetting without binder-typical raw material

| ● Aluminum | ● CausticmagnesiaMgO | ● flyash | ● MAMaleic anhydride MA |

| ● Bentonite | ● Clay | ● Fluorspar | ● NaCISaltNaCI |

| ● CaOBurnt lime CaO | ● DimethylterephthalateDMT | ● Gypsum | ● Sodium cyanide NaCN |

| ● Caustic dolomite | ● Fluedust | ● Lateritic iron ore | ● Woodchips |

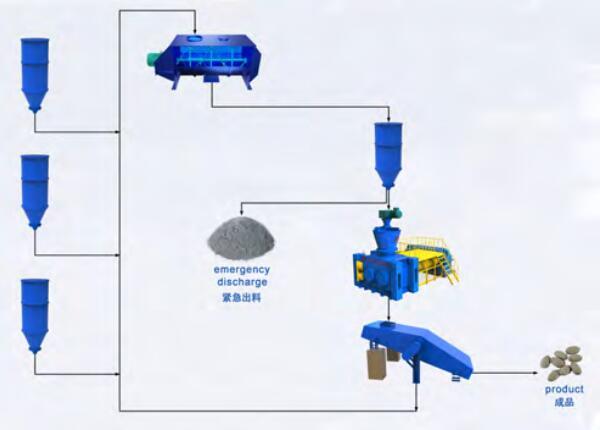

Single Roller Press

Multiple Roller Press

Finished product

Briquetting with Binder

● Briquetting with binder-typical mixes

● Chrome ore with molasses/hydrated lime

● Coal with bitumen

● Coke fines with starch

● Copper-nickel concentrate with lignosulfonate

● DR/HBI plant residues with bentonite

● DRI fines with molasses/hydrated lime or sodium silicate/hydrated lime

● Feed for RHF-based DR process with starch

● Molybdenumoxidewithammonia solution

● Nickel powder with PVA

● Steel plant residues with molasses/hydrated lime

For cold briquetting at feed material temperatures of up to 100°C, it may be necessary to add binders to improve the briquette- forming characteristics.

Binders are primarily used for the briquetting of substances that have inadequate adhesive properties and are thus otherwise unsuitable for the production of firm briquettes. An example is the ubiquitous egg- -shaped coal briquette, which has been produced from coal fines for well over 100 years. Today, briquettes are usually illow- -shaped, with sizes ranging from 15 to 60cml. However, depending on the material to be briquetted and the customer's specific requirements, other forms and sizes of briquette are possible.

A variety of binding agents is available, but certain criteria need to be met for the right choice of binder. Clearly, the binder must function properly and the briquettes need to be robust enough to withstand handling on the way from the roller press to their usage destination. The subsequent processing also has its specific requirements; for example, a binder that corrodes the lining of a mtallurgical vessel will not be suitable, no matter how good its physical properties may be. And from an economic point of view, the binder must be available in sufficient quantties and at an acceptable price per ton of product.

Binders can be classified as:

● glucosidic (e.g. molasses, starch)

● inorganic solutions (e.g. sodium silicate)

● clays(e.g. bentonite)

● thermoplastic (e.g. bitumen, pitch)

● mortar-type(e.g. cement, hydrated lime)

● non-glucosidic organic solutions (e.g.resins)

● fibers(e.g. paper fuf)

Keywords: DH series dry type roller press compactor

Recommended Products

fy@fuyigz.com

fy@fuyigz.com

0086-519-80181222

0086-519-80181222

fy@fuyigz.com

fy@fuyigz.com

+61 426861120

+61 426861120

Message

Message