Products&Technology

Category

Potassium sulfate granulation line

Category: Engineering Case

Potassium sulfate granulation line is an essential part of potassium fertilizer production. The granulation line is used to produce potassium sulfate granules, which are highly effective in promoting plant growth and increasing crop yields. The process involves mixing potassium sulfate with other organic or inorganic materials, which are then compressed into small granules.

Potassium sulfate granulation line is an essential part of potassium fertilizer production. The granulation line is used to produce potassium sulfate granules, which are highly effective in promoting plant growth and increasing crop yields. The process involves mixing potassium sulfate with other organic or inorganic materials, which are then compressed into small granules.

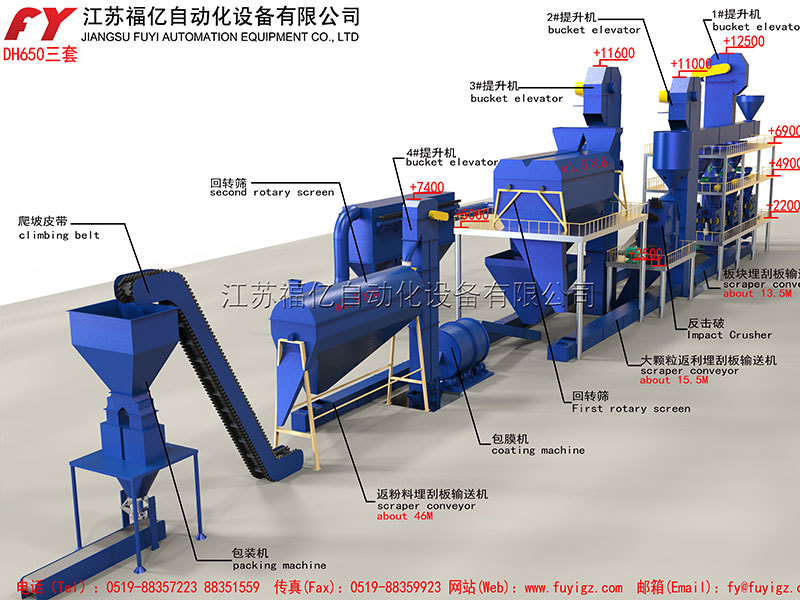

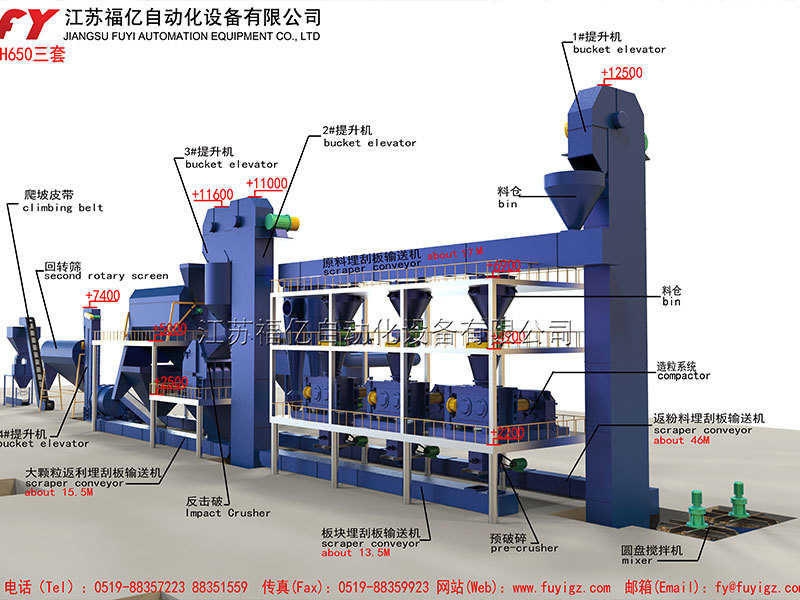

The granulation line consists of various equipment, such as a mixer, granulator, dryer, and cooler. The mixer is used to blend the raw materials, while the granulator compresses the mixture into granules of the desired size. The dryer removes excess moisture from the granules, and the cooler cools them down after the drying process.

The production of high-quality potassium sulfate granules requires careful attention to detail and adherence to strict quality control measures. The process must be closely monitored to ensure that granules are consistent in size, shape, and composition. This is essential to ensure the effectiveness of the fertilizer and to meet the needs of farmers and growers.

In conclusion, the potassium sulfate granulation line is an essential component of potassium fertilizer production. It is a complex process that requires specialized equipment and careful attention to detail. By producing high-quality granules, potassium sulfate fertilizers can help farmers and growers increase crop yields and promote plant growth.

Keywords: Potassium sulfate granulation line

Recommended Products

fy@fuyigz.com

fy@fuyigz.com

0086-519-80181222

0086-519-80181222

fy@fuyigz.com

fy@fuyigz.com

+61 426861120

+61 426861120

Message

Message