News & Events

Disc-Pelletizer Mixer: The Key to Efficient Building Material Processing

Release time: 2023-05-12

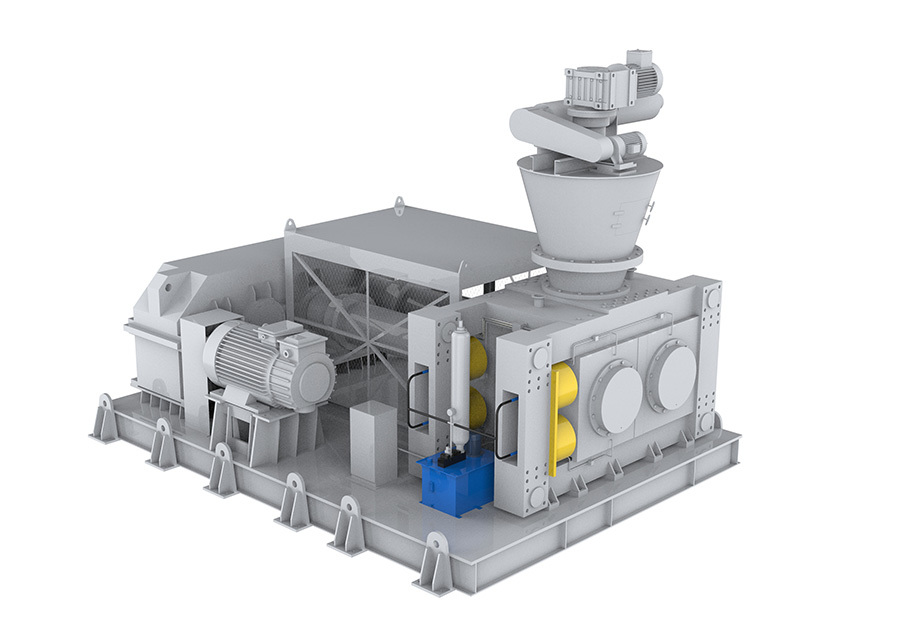

The disc-pelletizer mixer is a crucial component in the manufacturing industry, specifically for building material processing. This machine is used to efficiently agglomerate and pelletize various materials such as clays, limestone, and sand. By doing so, it makes the materials easier to handle, transport, and use in various applications.

One of the advantages of the disc-pelletizer mixer is its ability to produce consistent, high-quality pellets. This results in a more efficient production process, as well as a higher-quality end product. Additionally, the machine is versatile and can handle a wide range of materials and sizes.

Another benefit of the disc-pelletizer mixer is its energy efficiency. It consumes less power compared to other machines, making it a more cost-effective option for businesses looking to optimize their production processes.

Furthermore, the disc-pelletizer mixer is designed to be low-maintenance, which reduces downtime and increases productivity. Its simple design also makes it easy to operate and clean.

In conclusion, the disc-pelletizer mixer is an essential machine for businesses in the building material processing industry. It offers numerous advantages over other machines, such as consistent pellet quality, energy efficiency, versatility, and low maintenance. By investing in a disc-pelletizer mixer, businesses can optimize their production processes, improve their end product, and ultimately, increase their profitability.

One of the advantages of the disc-pelletizer mixer is its ability to produce consistent, high-quality pellets. This results in a more efficient production process, as well as a higher-quality end product. Additionally, the machine is versatile and can handle a wide range of materials and sizes.

Another benefit of the disc-pelletizer mixer is its energy efficiency. It consumes less power compared to other machines, making it a more cost-effective option for businesses looking to optimize their production processes.

Furthermore, the disc-pelletizer mixer is designed to be low-maintenance, which reduces downtime and increases productivity. Its simple design also makes it easy to operate and clean.

In conclusion, the disc-pelletizer mixer is an essential machine for businesses in the building material processing industry. It offers numerous advantages over other machines, such as consistent pellet quality, energy efficiency, versatility, and low maintenance. By investing in a disc-pelletizer mixer, businesses can optimize their production processes, improve their end product, and ultimately, increase their profitability.

Keywords: disc-pelletizer mixer

fy@fuyigz.com

fy@fuyigz.com

0086-519-80181222

0086-519-80181222

fy@fuyigz.com

fy@fuyigz.com

+61 426861120

+61 426861120

Message

Message