News & Events

Compaction Granulation Technology in Building Materials Processing Machinery

Release time: 2023-05-16

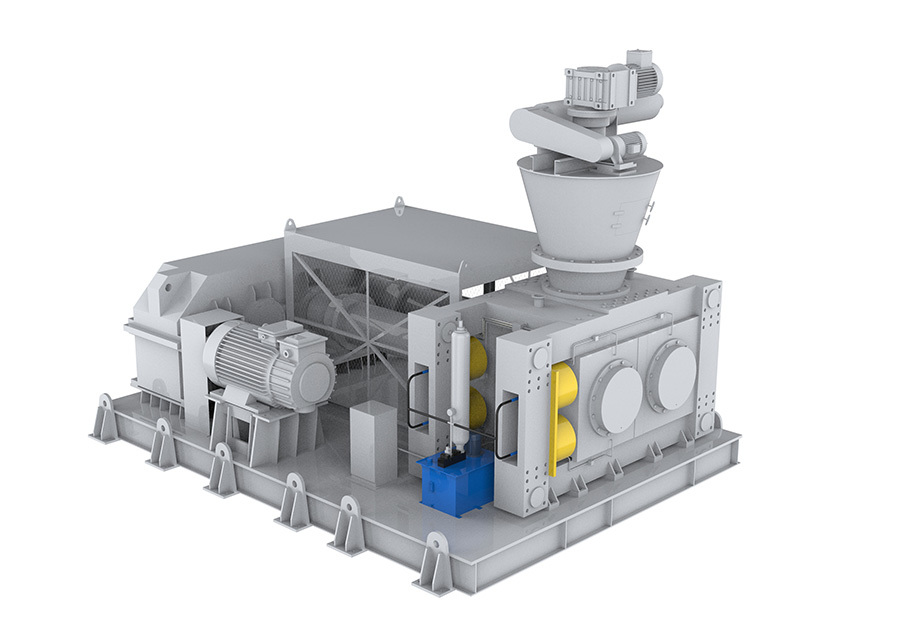

Compaction granulation technology is a ground-breaking process that has revolutionized the building materials processing machinery industry. It involves the use of pressure to compress and compact different materials into uniform shapes and sizes. This method has gained popularity due to its ability to improve product quality, enhance production efficiency, and reduce environmental impact.

One of the main benefits of compaction granulation technology is its ability to produce high-quality products. The process involves reducing the particle size of raw materials, which enhances their homogeneity and eliminates inconsistencies in the final product. Additionally, the high-pressure compaction process results in a product with superior strength and durability, making it ideal for use in the construction industry.

Another advantage of compaction granulation technology is its ability to improve production efficiency. The process is highly automated, which reduces the need for manual labor and increases throughput. Additionally, the uniformity of the final product reduces material waste, saving time and money in the production process.

Finally, compaction granulation technology is environmentally sustainable. The process uses minimal water and produces significantly less waste compared to traditional manufacturing processes. This reduces the impact on the environment and improves the overall sustainability of the production process.

In summary, compaction granulation technology is a game-changer in the building materials processing machinery industry. Its ability to enhance product quality, increase production efficiency, and promote environmental sustainability makes it a must-have technology for any manufacturer in the industry.

One of the main benefits of compaction granulation technology is its ability to produce high-quality products. The process involves reducing the particle size of raw materials, which enhances their homogeneity and eliminates inconsistencies in the final product. Additionally, the high-pressure compaction process results in a product with superior strength and durability, making it ideal for use in the construction industry.

Another advantage of compaction granulation technology is its ability to improve production efficiency. The process is highly automated, which reduces the need for manual labor and increases throughput. Additionally, the uniformity of the final product reduces material waste, saving time and money in the production process.

Finally, compaction granulation technology is environmentally sustainable. The process uses minimal water and produces significantly less waste compared to traditional manufacturing processes. This reduces the impact on the environment and improves the overall sustainability of the production process.

In summary, compaction granulation technology is a game-changer in the building materials processing machinery industry. Its ability to enhance product quality, increase production efficiency, and promote environmental sustainability makes it a must-have technology for any manufacturer in the industry.

Keywords: compaction granulation technology

fy@fuyigz.com

fy@fuyigz.com

0086-519-80181222

0086-519-80181222

fy@fuyigz.com

fy@fuyigz.com

+61 426861120

+61 426861120

Message

Message