News & Events

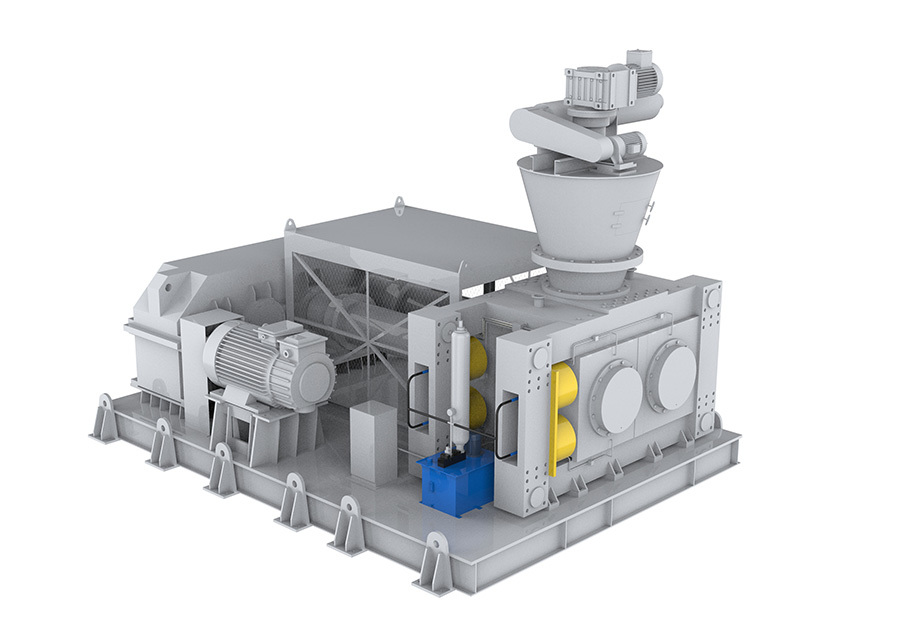

Roller Press Granulator: A Revolutionary Machine for Building Materials Processing

Release time: 2023-05-22

Roller press granulators are machines designed for granulating powdery materials into pellets. They are widely used in the production of building materials like cement, fertilizer, and chemical products. This machine is gaining popularity due to its numerous benefits that set it apart from traditional granulating machines.

One of the key advantages of roller press granulators is their high efficiency. Unlike other granulators that require multiple stages of processing, roller press granulators can complete the entire process in a single step. This not only saves time but also reduces the cost of production.

Another benefit of roller press granulators is their ability to produce uniform and high-quality pellets. This is achieved through the use of a unique extrusion mechanism that ensures the granules are formed with consistent size and shape. This consistency is crucial in ensuring the quality of the final product.

Roller press granulators are also versatile machines that can handle a wide range of materials. They can process materials with different properties like moisture content, viscosity, and adhesiveness. This makes them suitable for processing a variety of building materials.

In conclusion, roller press granulators are a game-changer in the field of building materials processing machinery. They offer high efficiency, produce uniform and high-quality pellets, and can handle a wide range of materials. With these benefits, they are a must-have for any building materials manufacturer looking to improve their production processes.

One of the key advantages of roller press granulators is their high efficiency. Unlike other granulators that require multiple stages of processing, roller press granulators can complete the entire process in a single step. This not only saves time but also reduces the cost of production.

Another benefit of roller press granulators is their ability to produce uniform and high-quality pellets. This is achieved through the use of a unique extrusion mechanism that ensures the granules are formed with consistent size and shape. This consistency is crucial in ensuring the quality of the final product.

Roller press granulators are also versatile machines that can handle a wide range of materials. They can process materials with different properties like moisture content, viscosity, and adhesiveness. This makes them suitable for processing a variety of building materials.

In conclusion, roller press granulators are a game-changer in the field of building materials processing machinery. They offer high efficiency, produce uniform and high-quality pellets, and can handle a wide range of materials. With these benefits, they are a must-have for any building materials manufacturer looking to improve their production processes.

Keywords: Roller press granulator

fy@fuyigz.com

fy@fuyigz.com

0086-519-80181222

0086-519-80181222

fy@fuyigz.com

fy@fuyigz.com

+61 426861120

+61 426861120

Message

Message