News & Events

All You Need to Know About Roller Press Granulator Factories for Building Material Machinery

Release time: 2023-06-05

If you're in the building material machinery industry, you're likely familiar with the process of granulation, in which small particles are compressed into larger ones. One popular method of granulation is roller press granulation, which is used to create fertilizer, building materials, and more.

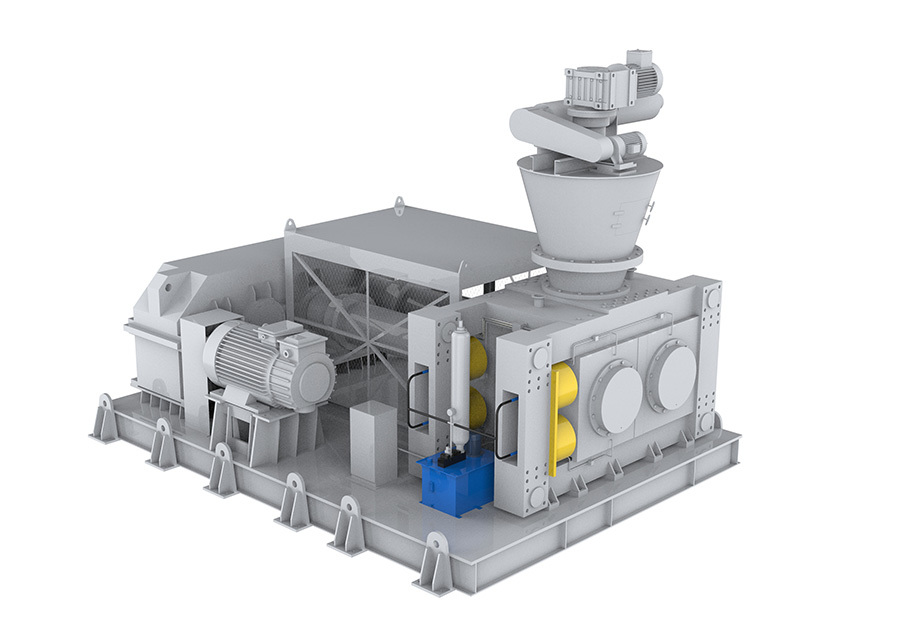

A roller press granulator factory is a manufacturing facility that specializes in producing roller press granulators. These factories typically use high-pressure rollers to compress materials into the desired shape and size. The rollers can be adjusted to create granules of different sizes and densities, making this method of granulation highly versatile.

Roller press granulators have a number of advantages over other granulation methods. For one, they're highly efficient, producing granules quickly and with minimal waste. They're also highly customizable, allowing for granules with different properties to be produced for different applications.

In addition to fertilizer and building materials, roller press granulators can also be used to produce animal feed, fuel pellets, and more. As such, these factories are an important part of many different industries.

When choosing a roller press granulator factory, it's important to look for a facility that uses high-quality materials and equipment. Additionally, you'll want to work with a factory that has a proven track record of producing high-quality granules that meet your specific needs.

In conclusion, roller press granulator factories are an important part of the building material machinery industry. By using high-pressure rollers to compress materials into granules, these factories produce a wide range of materials for use in various applications. Whether you're looking to produce fertilizer, animal feed, or building materials, roller press granulators are a highly efficient and versatile choice.

A roller press granulator factory is a manufacturing facility that specializes in producing roller press granulators. These factories typically use high-pressure rollers to compress materials into the desired shape and size. The rollers can be adjusted to create granules of different sizes and densities, making this method of granulation highly versatile.

Roller press granulators have a number of advantages over other granulation methods. For one, they're highly efficient, producing granules quickly and with minimal waste. They're also highly customizable, allowing for granules with different properties to be produced for different applications.

In addition to fertilizer and building materials, roller press granulators can also be used to produce animal feed, fuel pellets, and more. As such, these factories are an important part of many different industries.

When choosing a roller press granulator factory, it's important to look for a facility that uses high-quality materials and equipment. Additionally, you'll want to work with a factory that has a proven track record of producing high-quality granules that meet your specific needs.

In conclusion, roller press granulator factories are an important part of the building material machinery industry. By using high-pressure rollers to compress materials into granules, these factories produce a wide range of materials for use in various applications. Whether you're looking to produce fertilizer, animal feed, or building materials, roller press granulators are a highly efficient and versatile choice.

Keywords: Roller press granulator factory

fy@fuyigz.com

fy@fuyigz.com

0086-519-80181222

0086-519-80181222

fy@fuyigz.com

fy@fuyigz.com

+61 426861120

+61 426861120

Message

Message