Products&Technology

Category

compaction granulation technology

Category: New Equipment

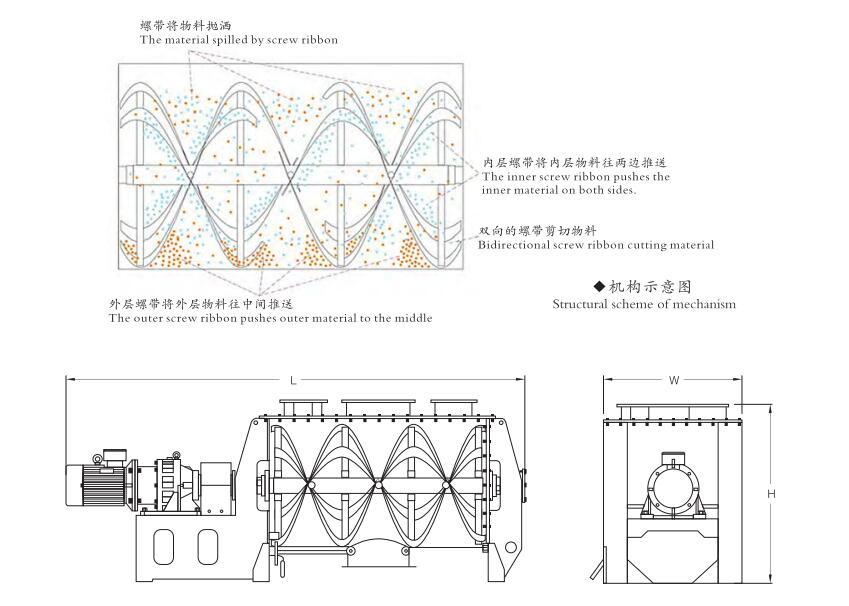

Horizontal ribbon mixer composed of U shaped tube, spiral blade and transmission parts;helical ribbon blades are generally made of double lqyer,at work,the outer helical belt make materials collected from both sides to the central layer,and the inner helical belt transport materials from the central to the two sides,and the convective mixing is formed.Mixing parts can also be made into a paddle or increased knife,adapt to different materials.The cylinder cover can be made of the arch or fully-opened,arch can be under pressure,fully-opened is convenient to clean equipment inside. The machine has the advantages of wide application range, high mixing uniformity, short mixing time and large loading coefficient.

Product overview

Horizontal ribbon mixer composed of U shaped tube, spiral blade and transmission parts;helical ribbon blades are generally made of double lqyer,at work,the outer helical belt make materials collected from both sides to the central layer,and the inner helical belt transport materials from the central to the two sides,and the convective mixing is formed.Mixing parts can also be made into a paddle or increased knife,adapt to different materials.The cylinder cover can be made of the arch or fully-opened,arch can be under pressure,fully-opened is convenient to clean equipment inside. The machine has the advantages of wide application range, high mixing uniformity, short mixing time and large loading coefficient.

Working principle

Stirrer shaft,the outer helical belt with power driven,the coiled form with the rotation direction push materials from both ends of the U-shaped positions to the center ,and inner helical belt push materials from the center to both ends, the convective mixing is formed.

At the bottom central of horizontal ribbon mixer cylinder opening discharging port,the outer helical belt with main shaft rotation direction drive cylinder inner wall material to central material discharging mouth,ensure that no dead angle of material discharge in the cylinder.

Application area

The horizontal screw mixer is suitable for mixing powder with powder, granule and powder, powder and small amount of liquid,widely used in chemical, pharmaceutical, food, feed, plastic and building materials industries, can be produced according to GMP standards. The utility model has the advantages of wide adaptability to the mixture, homogeneous mixing of the viscous material, and the particle material as much as possible to keep the particles intact, and can mix the materials with a mixture ratio of 1:1000 to 10000. The machine can also make heating, cooling, positive pressure, vacuum and other special forms according to the user's requirements.

Structure characteristics

The machine is a horizontal cylinder,the inner and outer two layers of helical belts have unique structure, stable operation, reliable quality, low noise, long service life, convenient installation and maintenance, and a wide range of agitator structure, versatile mixing equipment. The mixing effect of horizontal ribbon mixer is not affected by the particle size and density. The mixing speed is fast, the mixing uniformity is high, and the spiral belt can be provided with a scraper, and the mixing effect of the viscous material is good.

The mixing speed is fast, the mixing uniformity is high, especially sticky,and the helical belt can be installed with a scraper, and the mixing effect of the viscous material is good.

Requires a mix of different materials (special materials must each mixing needs cleaning), using different helical belt structure,heating and drying of the jacketed type.

The positive and negative rotating spiral strips are arranged on the same horizontal axis , form a low power and high efficient mixed environment.stable mixing process reduce the damage to the fragile material,the installation structure also has the role of crushing knife,can also be equipped with liquid injection system,the liquid and power better fully uniform mixing.

Can also open cleaning door on the horizontal body, in order for the user to clean. Equipment overall height is low, easy to install.

Technical specifications

| Model specification | Motor power(kw) | Speed(r/min) | Mixing quantity (m3) | L×W×H(mm) | Equipment weight (kg) |

| WLDH-0.05 | 2.2 | 76 | <30 | 900×500×10 | 280 |

| WLDH-0.1 | 2.2 | 76 | <60 | 1080×758×615 | 330 |

| WLDH-0.3 | 4 | 66 | <180 | 1550×812×1015 | 780 |

| WLDH-0.5 | 5.5 | 66 | <300 | 1975×1059×1120 | 955 |

| WLDH-1 | 11 | 41 | <600 | 2340×1380×1455 | 1400 |

| WLDH-1.5 | 15 | 37 | <900 | 2430×1450×1600 | 2000 |

| WLDH-2 | 18.5 | 33 | <1200 | 2480×1651×1800 | 2500 |

| WLDH-2.5 | 22 | 33 | <1500 | 2700×1700×1850 | 2900 |

| WLDH-3 | 22 | 33 | <1800 | 2945×1896×1980 | 3300 |

| WLDH-4 | 22 | 29 | <2400 | 3038×1946×2205 | 3600 |

| WLDH-5 | 30 | 29 | <3000 | 3932×2010×2035 | 4620 |

| WLDH-6 | 37 | 26 | <3600 | 3938×1882×2246 | 5300 |

| WLDH-8 | 45 | 26 | <4800 | 3986×2160×2516 | 6800 |

| WLDH-10 | 55 | 23 | <6000 | 4500×2270×2667 | 8900 |

| WLDH-12 | 55 | 21 | <7200 | 4500×2466×2785 | 9520 |

| WLDH-15 | 75 | 21 | <9000 | 5363×2470×3020 | 9950 |

| WLDH-20 | 75 | 19 | <12000 | 5670×2650×3150 | 11140 |

| WLDH-25 | 90 | 17 | <15000 | 6800×2730×3200 | 15500 |

| WLDH-30 | 110 | 17 | <18000 | 8500×2800×3300 | 16000 |

Keywords: compaction granulation technology

Recommended Products

fy@fuyigz.com

fy@fuyigz.com

0086-519-80181222

0086-519-80181222

fy@fuyigz.com

fy@fuyigz.com

+61 426861120

+61 426861120

Message

Message